Many Canadian oil and gas facilities use heat management systems that operate well as a failsafe. However, the traditional method of simply waiting for issues to happen and then correcting them is risking downtime of the process your facility relies on for revenue. Too many failures in your production line could signal that expensive maintenance is on the horizon.

The best way to avoid temperature related system failures is to prevent problems before they become critical issues. Maintenance teams can help accomplish this by implementing sophisticated thermal imaging technology that offers unparalleled accuracy in remote system diagnosis.

What is Thermal Imaging?

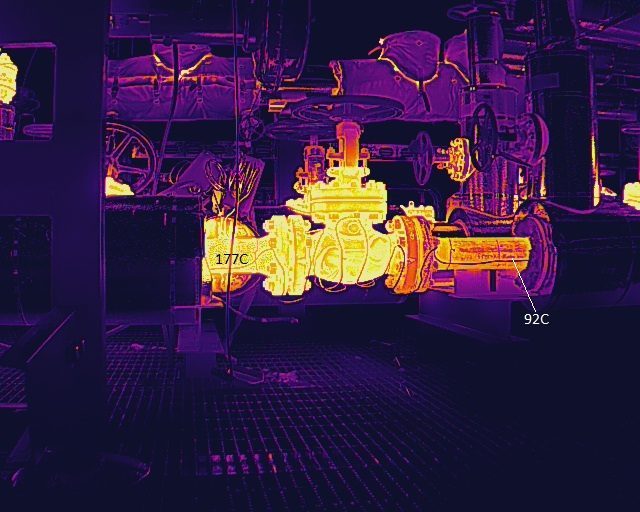

Thermal imaging involves using handheld cameras and drones to produce thermal images of your insulation and heat trace system with unprecedented accuracy, no matter how big or complex your system is. Our engineers analyze the information to determine how your HMS is performing and recommend improvements based on the information to ensure the system maintains the process temperatures required for reliable, ongoing performance.

Thermal imaging is comprised of two primary services:

Temperature Maintenance Inspection

This service uses aerial/UAV and thermal imaging technology for remote, real-time monitoring of your Heat Management System providing temperature readings of the entire asset, enabling MSCP technicians to:

- Remotely detect potential failure points caused by wet insulation or heat trace failure

- Locate the heat sinks with enhanced accuracy

- Detect anomalies such as EHT failure locations throughout the heat management system

MSCP’s Temperature Maintenance Inspection is a must-have service for critical process lines either being commissioned or already in operation.

Heat Management Integrity Inspection

Critical system failures can take you by surprise when caused by things you can’t see with the naked eye. Our Heat Management Integrity Inspection detects potential problems at any site location with pinpoint accuracy, including:

- Wet or damaged insulation resulting in hot or cold spots

- Improper insulation installation that leads to air gaps

- Damaged or oversized insulation exposing the EHT

- Excessive heat loss through heat sinks

Customers who utilize our unique approach to HMS preventive maintenance reap several significant cost-effective and time-saving benefits, allowing them to take proactive steps toward protecting their system against failure at a lower price point.

Here are some of the more tangible benefits our Heat Management Integrity Inspection brings:

- Service does not require scaffolding or rope access

- Increased accuracy of readings with real-time system monitoring

- Remotely detects critical deficiencies in EHT and insulation

- Minimal set-up time

- Optimized cost savings

- Increased efficiency and accuracy in HMS and insulation inspections

The information gathered by the inspections is compiled into a comprehensive report that details the findings and presents preventative action that should be taken on the HMS and pipe insulation.

Read More: What Is A Heat Management Solution?

Drone Thermal HMS Inspection Report

The most impactful part of the thermal imaging process is the Drone Thermal HMS Inspection Report, which details the results of the work and provides recommendations on further steps to protect the HMS and insulation system from failure.

The report is broken down into six sections, each packed with valuable information that helps further the understanding of the pipe system:

- Introduction: This opening section details the thermal imaging process, what it accomplishes, and why companies should use it.

- Purpose: Customized details of why MSCP is using thermal imaging technology for that particular project and the outcomes from the inspection and report to expect.

- Equipment setup: Detailing the technology used for the inspections, including weight and camera-resolution specifications.

- Flight information: Location details of the site to be inspected, as well as weather, temperature, and wind speed data and job completion time.

- Visual and thermal image analysis: Crisp, clear images from the aerial inspection, including side-by-side comparisons with the thermal photos taken at the site to demonstrate how thermal images offer a superior level of information.

- Conclusion and future recommendations: Detailed analysis of the information captured by the thermal images, highlighting areas of improvement where proactive steps can be taken to optimize the pipe system and prevent system failure.

We design our Drone Thermal HMS Inspection Report to provide the details Canadian oil & gas facilities need to help ensure the continued efficiency of their operations. With one clearly-written document featuring high-quality images, facility managers have all the information they need to prevent problems before they become critical issues, backed by MSCP technicians dedicated to their success.

Read More: Benefits of Digital Work Packages and Reporting

The MSCP Difference

At MSCP, our goal is to help your facility achieve zero downtime due to heat management issues with tech-driven, cost-effective solutions that eliminate the worry of freezing temperatures affecting production and triggering expensive downtime. Contact us anytime to learn more about how we can help you.