Heat management maintenance is the cornerstone of keeping your oil and gas facility operating at peak efficiency. However, many facility operators we’ve spoken with are concerned about balancing the most efficient ways to access their systems for inspection with the associated costs.

Traditionally, oil and gas technicians have used one or a combination of four ways to access their heat management systems and troubleshoot issues. Some carry unique advantages and disadvantages, depending on your facility’s setup.

Access Your Heat Management System With Boots On The Ground

As the name implies, this method involves using a ladder or stairs to inspect equipment either at ground level or accessible by a permanent structure. It’s the easiest and most cost-effective way to troubleshoot your heat management system, but equipment that is at a high elevation may be out of range by boots alone. This means augmenting the boots method with other solutions to access system components high above the ground.

Access Your Heat Management System By Stepladder Or Mobile Equipment

Heat management technicians often use an appropriately-sized ladder or a piece of mobile equipment like an elevated work platform (EWP) to access system parts located at a high elevation. The components to be inspected must be in a clear area and have limited obstructions to accommodate the ladder or EWP. Ladders are very cost-effective to use for this application. However, EWPs can carry additional costs as they often need to be rented and delivered. They also require operator-specific training for the type and size of EWP being utilized.

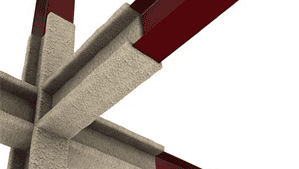

Access Your Heat Management System Using Scaffolding

Using a scaffold is one of the most versatile methods of accessing at-height equipment for inspection and troubleshooting. However, it also comes at a high cost. Scaffolding requires a lot of labour, often hired from external sources, to erect and tear down after use. Purchasing or renting scaffolds also requires considerable investment. In addition, the amount of time needed for the job site is usually measured in hours or days, making scaffolding one of the least cost-effective methods of accessing, maintaining, and troubleshooting your facility’s heat management system.

Access Your Heat Management System With Rope Access (IRATA)

Rope access gives you all the same access as scaffolding but at a fraction of the cost and time. Instead of hiring a separate crew of scaffolders to build the access method, your existing Heat Management technicians trained as IRATA Level 1’s, 2’s, and 3’s can rig, access, and perform the work the same day. Not only is rope access incredibly efficient, but it’s also one of the safest methods in the industry. You can also save thousands by avoiding the high labour costs of setting up, using, and tearing down the scaffold.

Minimizing The Number Of Heat Trace Contractors

When facility operators use these four methods to access your heat management system, we often see substantial inefficiencies in how the work is divided between contractors.

For example, the “ground” contractor will be responsible for accessing the heat management system by “boots” or using stepladders or EWPs. In cases where there is work at height, they will have to coordinate with another contractor or group to build a scaffold and then tear it down when the job is completed. This can add days to the project lifecycle. Also, coordinating between contractors can be complex and time-consuming, adding avoidable costs to the job.

When a facility operator hires a rope access contractor, they save the time and money involved by avoiding the use of scaffolding. While this is an improvement on the traditional method, it also creates another handoff, splitting up project ownership. There can also still be challenges involved with coordinating between multiple contractors.

An ideal solution is hiring a ground contractor certified in rope access. This eliminates unnecessary handoffs between contractors, allowing one company to keep complete control of the heat management scope and increasing the reliability of the system. Rope access for heat management can reduce the use of scaffolding by over 95 percent, positively impacting the time needed to complete the job and your facility’s bottom line.

Read More: MSCP School

The MSCP Difference

Segregating scopes in heat trace maintenance can increase costs, decrease productivity, complicate communications, and lessen accountability. The additional costs associated with this approach can run in the thousands.

In addition, many separate contractors only concentrate on their system segment without knowing or understanding the other aspects of the overall picture. These short-term relationships can inhibit predictable work, affecting the quality and performance of your system.

MSCP heat trace technicians are fully-trained and IRATA-qualified in rope access, providing our customers with a one-stop solution that covers every aspect of their heat management systems. MSCP’s approach removes the need to work with multiple contractors and juggle several moving parts simultaneously. With one phone call to MSCP, we’ll handle the entire job efficiently, reliably, and cost-effectively.

Our goal at MSCP is to help your facility achieve zero downtime due to heat management issues with comprehensive end-to-end heat management maintenance designed to ensure your operation stays productive and profitable.

Read More: Our Services

Contact us anytime to learn more about how we can help you.