Fireproof coverage of fire-sensitive components has been a staple of oil and gas facilities for decades. Although plant designs have evolved due to emerging tech, smaller footprints, taller process units, and increased regulations, fire protection solutions have stayed relatively the same since they were first introduced.

The traditional two-phase method of fireproofing involves installing a mesh screen with metal corner beads to support the structure, followed by spraying and troweling at least two layers of the fireproofing material. This aging, labour-intensive method creates challenges with safety and control, especially in tight-access areas, and requires a long curing time. Corrosion of steel under current fireproof products results in significant repair costs, increasing with each passing season. Overall, installations only last up to ten years and require ongoing maintenance, which is generally only budgeted once reliability is compromised.

This method can no longer support the growing market. Facility owners demand reliable fireproofing products that are cost-efficient, safe to install, protect against corrosion, and reduce maintenance schedules.

MSCP has answered the call for better fire protection with a new cost-effective solution that offers superior performance for up to 50 years with a single application: Geopolymer Solutions’ (GS) FP250 Cold Fusion Concrete (CFC), the world’s first and only UL1709-listed Geopolymer concrete fireproofing.

Read More: Our Services

What Makes CFC FP250 A Superior Fireproofing Solution?

Geopolymer Solutions, LLC, which originated as a chemical and acid-resistant cement and concrete manufacturer, replaced traditional properties found in fireproofing products such as Portland Cement and caustic soda with various products such as fly ash, granulated ground blast furnace slag (GGBFS), and sodium metasilicate. When blended, these ingredients produce calcium silicate aluminum hydrate (CSAH), a glassy aluminate similar to mineral materials such as zeolites, which are highly durable and chemical resistant.

CFC FP250 also contains various proprietary products, including a protein, a shrinkage compensator, alkali-resistant glass fibers, water reducers, and a set time retarder (sodium tetraborate) that enhances the penetration ability of the sodium silicate.

This innovative mixture adds up to some impressive product statistics:

- Compressive strength ranges from 2,500 to 4,000 PSI

- Bond strength ranges from 10,000 to 25,000 PSF

- Application surface temperature resistance of up to 149° C

- Operation temperature resistance of up to 538° C

What Are The Benefits Of Using CFC FP250?

Facility owners can now access several cost-saving benefits by switching to the innovative high-performance CFC FP250 offers, including the following:

EASIER APPLICATION

The product’s built-in rust inhibitor removes the need to prime steel; only a minor surface descaling is needed. Without having to install mesh and corner beads, access to tight spaces by contractors is much easier.

SUPERIOR CORROSION RESISTANCE

The activated sodium silicate penetrates and protects the steel on an electrochemical basis, aided by sodium tetraborate (borax). The result is superior rust protection over the long term without additional processes.

SIGNIFICANT REDUCTION IN SCHEDULING

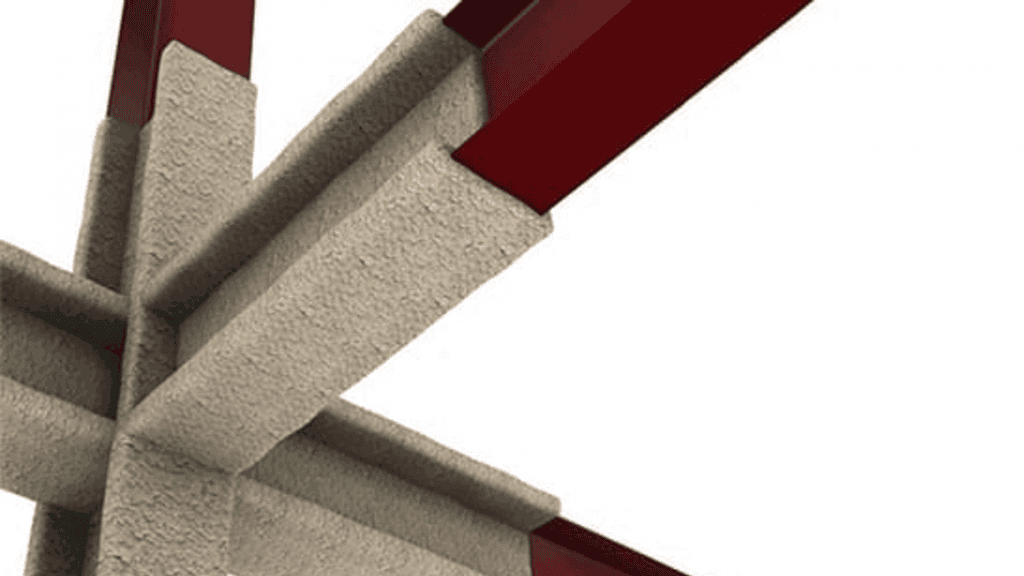

CFC FP250 bonds chemically to steel in one pass, 1.5” thick on the underside of a steel component without forming. This eliminates the need for sandblasting, priming, or using laths during the application, reducing scheduling and improving on-the-job safety.

LONGER LASTING PERFORMANCE

Traditional fireproofing usually lasts eight to ten years before a reapplication is required. The CFC FP250 solution lasts up to 50 years with relatively little maintenance. Minimal shrinkage reduces the need for recaulking, nor is there a need to maintain seals due to the internal deterioration of the mesh and open voids. Reduced maintenance saves time and money for decades longer than the standard fireproofing methods.

EXTENDED FIREPROOFING SEASON

Teams can install this solution quickly in lower temperatures, extending the fireproof season by an average of six to eight weeks.

GREENEST FIREPROOF PRODUCT ON THE MARKET

Geopolymer cement production in CFC FP250 contributes up to 10 percent less of the greenhouse gases used to create Portland cement. It also contains 50 – 60 percent recycled content, making CFC FP250 more environmentally friendly.

FAST CURING TIME

Within four to five days after application, the solution will achieve a compressive strength of over 2,000 PSI and a bond strength of over 6,000 PSF. In addition, there will be no measurable water detected in the product after only four days, which means no shrinkage, expansion, or cracking during seasonal freezing and thawing.

MORE COST-EFFECTIVE

CFC FP250 offers a lower-installed price per metre than all other fireproofing products. It’s also much more cost-effective thanks to reduced maintenance and repairs.

SUPERIOR FIRE PROTECTION

Through rigorous UL 1709 testing, CFC FP250 offered superior protection at extreme temperatures.

MSCP: A Tradition Of Disruption Through Innovation

The CFC FP250 fireproofing solution aligns with MSCP’s goal of providing best-in-class innovation to help our clients achieve zero downtime due to heat management issues. Our one-stop-shop approach to heat trace solutions removes the need to work with multiple contractors and juggle several moving parts simultaneously.

With one phone call to MSCP, we’ll handle the entire job efficiently, including fireproofing, with unmatched reliability and cost-effectiveness, to help ensure your facility stays productive and profitable. Contact us anytime to learn more about how we can help you.